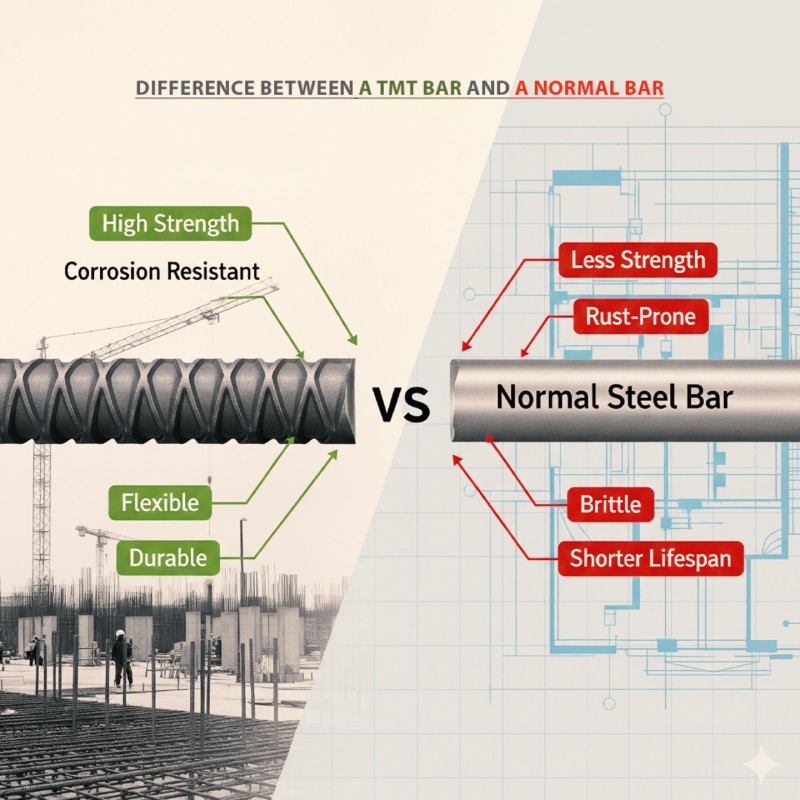

We should begin by knowing what we refer to by a "normal bar". This typically means in construction terms Mild Steel (MS) bars or plain bars. They are the old fashioned, conventional steel bars in concrete. They are crafted in steel and are fairly pliable and supple. They are weaker than modern bars and are also likely to deform when less weight or pressure is exerted. They tend to be plain, smooth and this is also a limitation because their surface is smooth so that their grip on the concrete is not always the strongest.

WHAT IS A TMT BAR??

TMT stands for Thermo-Mechanically Treated. This name describes the special process used to make them. TMT bars are the modern, advanced version of steel bars designed to be much stronger and safer. The key to a TMT bar is its unique manufacturing process, which gives it two distinct parts:

A Soft Inner Core: The inside of the bar remains soft and ductile (like a mild steel bar). This allows it to be bent on-site and, most importantly, to bend without suddenly snapping during an earthquake or other extreme events.

A Hard Outer Surface: The external surface of the bar is made very hard and tough, by a process of heat treatment and rapid cooling (quenching). This tough outer coating makes the bar highly strong.

-

209, Gowra Fountainhead, Patrika Nagar

Madhapur, Hyderabad - 500081 - Phone: +91 9100073039 Phone: +91 8121004773

- nsepoxy@gmail.com Website: www.nagarjunagroup.com

- Sitemap

Contact us

Contact us

NS Epoxy stands as the frontrunner in TMT manufacturing, committed to constant innovation and research. Our focus is to ensure our product technology remains cutting-edge, precisely tailored to meet client's requirements.